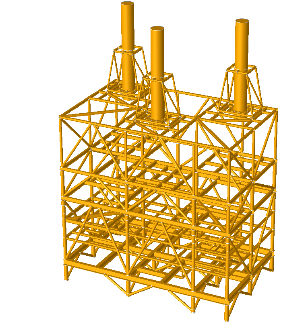

Longitude has been engaged for the structural design of a number of boiler modules for FPSO and FSLNG vessels ranging in size from approximately 200 tonnes up to 1400 tonnes which will see service in the North Sea, Offshore West Africa and in Asia.

In each case the scope of work involves structural design of the module to classification requirements as well as the vessel and owner requirements. Due to the complexity of the modules, Longitude has to work closely with the client to agree arrangements that avoid clashes with the extensive equipment, piping and electrical and instrumentation in the module.

All modules are designed for the following conditions:

- Strength in service and during transportation

- Lift condition

- Fatigue in service

- Vortex inducted vibration

- FPSO specific hull deflections

- Vessel motions

Within the module equipment and pipe support are designed and assessed as well as lifting equipment that is integrated within the module.

Longitude’s engineers and draftsmen prepare analysis and drawings using a range of software including SACS for the design of the primary structures and finite element analysis using FEMAP for the design of local structures and fatigue analysis.